Cabinet material: Made of national standard cold-rolled steel plate, high-grade stainless steel, and stainless steel SUS304L (food and beverage industry), SUS316L (medical drug industry), and SUS201 (economy stainless steel) can be selected. Compared to the 90 fold profile cabinet, it has higher air tightness, rigidity, and flexibility.

In terms of surface treatment: The steel plate, cabinet, base, and door surfaces are sprayed with plastic, and can be painted in any color according to needs. Stainless steel is generally treated with double-sided wire drawing.

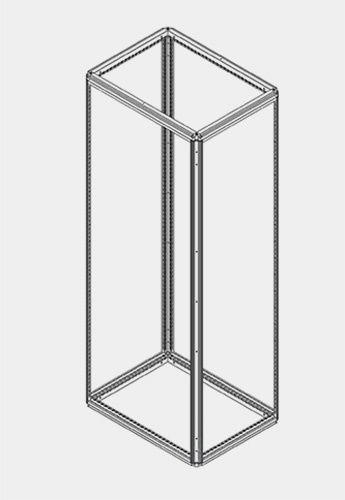

Cabinet standard configuration: 16 fold profile frame, front door, installation plate, back plate, top plate, side plate, base, lifting ring, three-section galvanized incoming line bottom plate, a pair of punched flower beams, pull rod three-point double tooth lock, process handle lock, cabinet door equipped with galvanized square tube, reinforcing ribs, and polyurethane coated foam sealing strip.

Cabinet process characteristics and performance: Generally, a special mold machine is used to produce 16 fold profiles, which have high strength, high precision, and are not easily twisted or deformed. The top plate can be removed, the side plate can be disassembled, and it is suitable for any direction of cabinet combination. The door corner can be extruded using specialized corner forming equipment, which is round and beautiful, without the need for welding and polishing.

Cabinet protection level: dustproof and waterproof level IP55, mechanical impact protection level IK10.